Model | 100 BPM | 150 BPM | 250 BPM |

Output/ Hour* | 6000 bottles. | 9000 bottles. | 12000 bottles. |

No. of Pocket Across | 10 | 12 | 20 |

Electrical Specifications** | |||

Main Motor | 1 HP/ 415 Volts/ 50 HZ | ||

Pump Two Nos. | 1 HP x 2 = 2 HP/ 415 Volts/ 50 Hz | 2 HP/ 415 Volts/ 50 Hz. | |

Electrical Heater | 3 KW. | 3 KW. | 3 KW. |

Conveyor | 0.5 HP/ 415 Volts/ 50 Hz | ||

Tank Capacity | 80 Ltrs. S.S 304 | ||

Wash Cycle | 3 Inner + 1 Outer + 1 AIr | ||

Cycle Timing | 3.5 Second for each wash + 1.5 second for travelling | ||

Water/ Air Consumptions | 400 Ltrs./ Hr/ Cycle/ Pressure 2.5 Kg@20 CFM | ||

Machine Dimensions (in mm) | 1150 x 2500 x 1550 | 1450 x 2500 x 1550 | 2900 x 2500 x 1130 |

Case Dimensions (in mm) | 1400 x 3000 x 2000 | 1900 x 3000 x 2000 | 3300 x 2500 x 2000 |

Net Weight | 1400 Kgs | 1600 Kgs | 2400 Kgs |

Gross Weight | 2000 Kgs | 2200 Kgs | 3000 Kgs |

Change Parts required | (A) Neck Dia. Bottle Holding Pocket. | ||

(B) Flat Container Size: Delivery Chute | |||

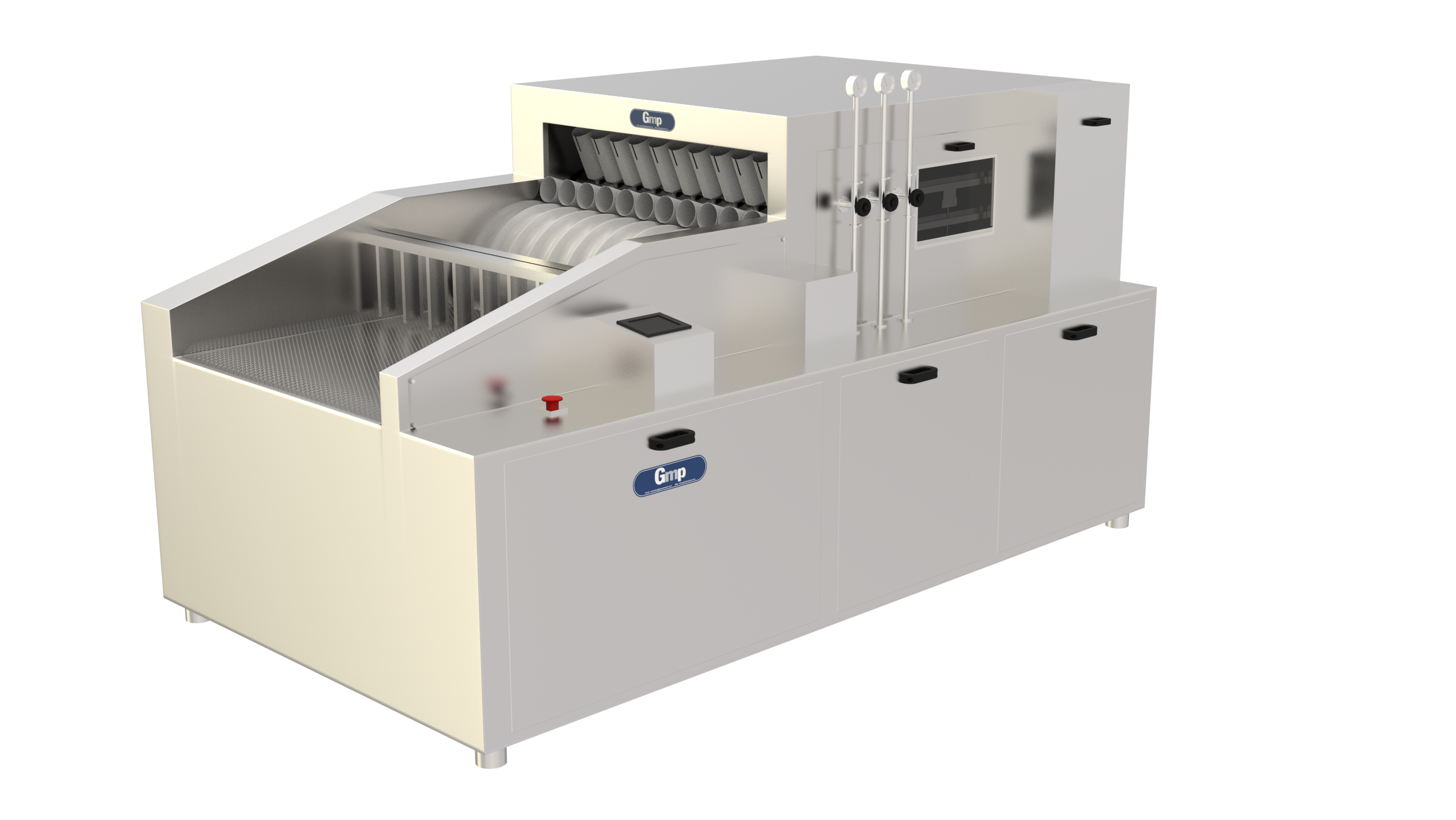

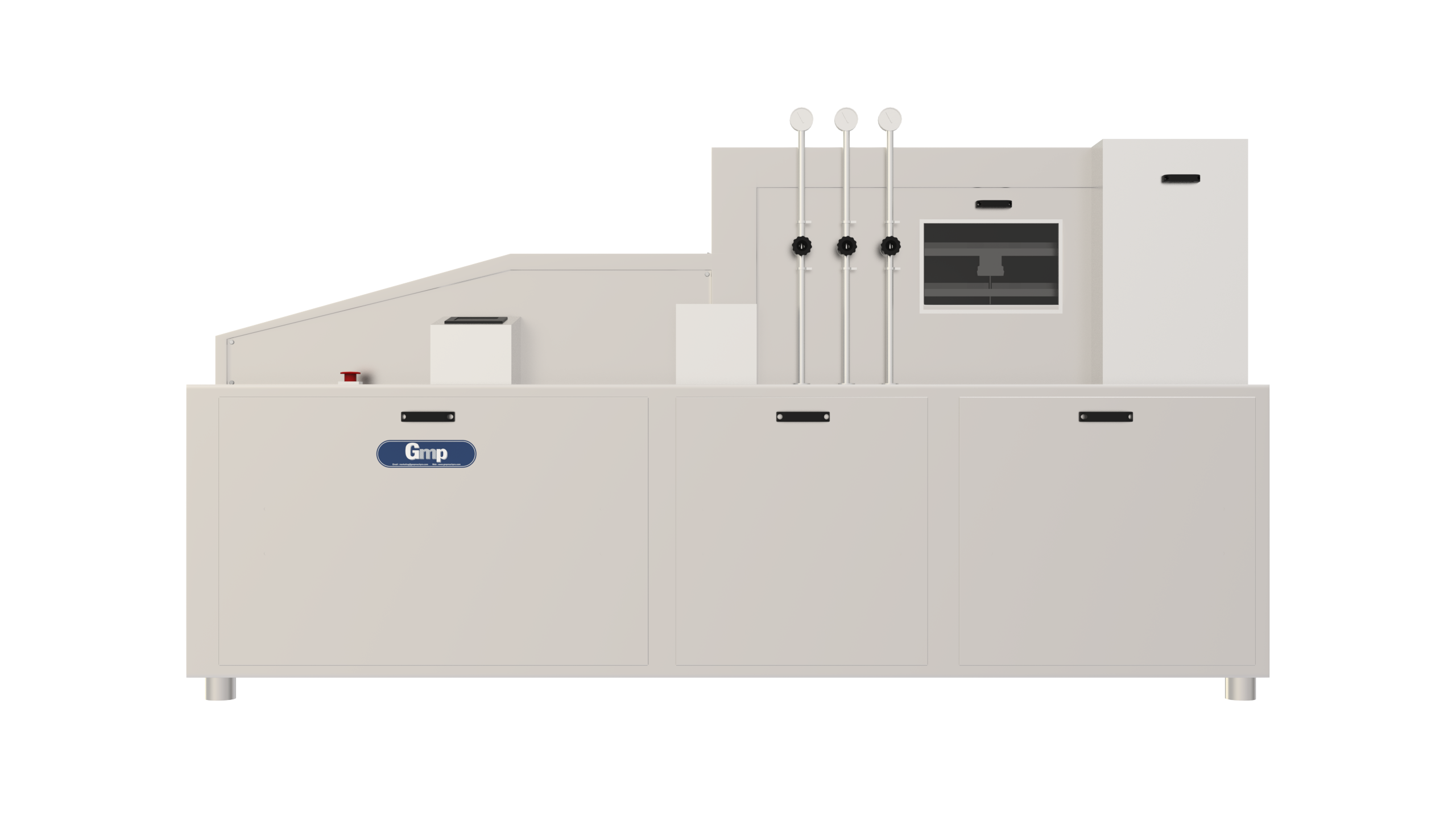

Automatic Linear Bottle Washing Machine

“GMP’s” High-Speed Linear Bottle Washing Machine is most ideal for Round Bottles and finds wide application in PHARMA, FOOD & BEVERAGES INDUSTRIES. The automatic loading arrangement facilities loading of bottles onto the SS wire mesh conveyor through the feed conveyor, or bottles are pushed manually from the feed table. This saves manpower as bottles are fed into pockets automatically. The automatic unloading mechanism consists of unloading bottle continues to turn table (Optional).

Salient Features:

• High-pressure spray nozzles ensure a perfect wash of Bottles.

• Interchangeable wash sequences.

• Totally fabricated from SS Materials, including the basic frame.

• No change parts required for washing of round bottles saving time of changeover. (Change Parts require for Flat bottles & if change of neck size.)

• All parts in contact with washing zones / jet are made from SS 316 materials.

• The machine is suitable for handling washes of round and flat glass bottles (With the help of change parts).

• Water re-cycling arrangement is possible as per the customer’s need.

• The machine is totally rigid and withstands continuous operation for long working hours without any trouble.

• Higher capacity centrifugal pump to wash bigger containers.

• Third Tank & pump can be fitted (optional).

Send Enquiry

Reviews

There are no reviews yet.